PRODUCT

Paper

spotting

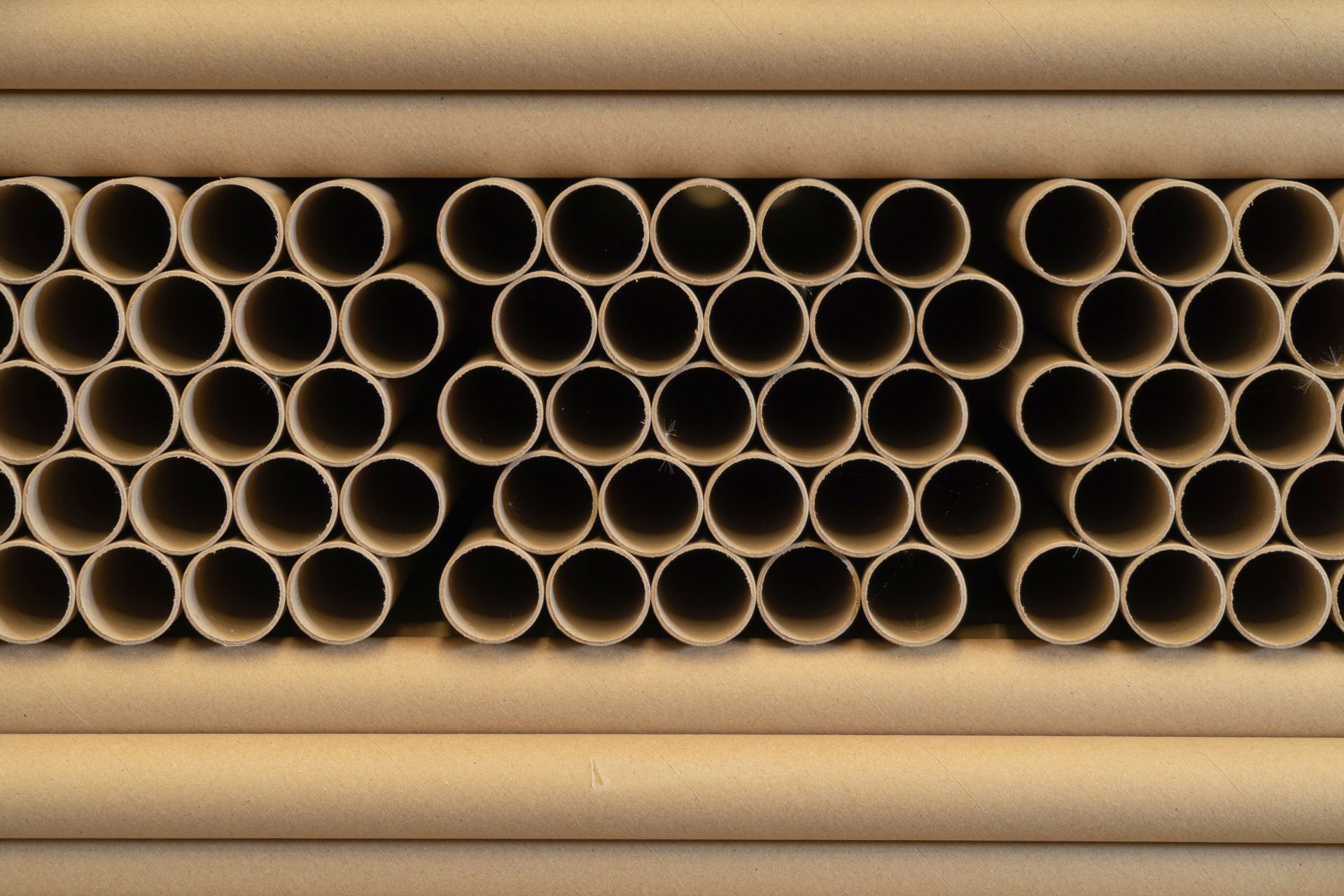

Made from paper scraps, a 100% recycled raw material, our paper can be developed in weights from 120g to 420g/m², delivered to the customer sliced into wafers or in 1600mm reels.

The formation of Pulp Maculature Paper is carried out in a round shape, generating better performance in the tube, barrel and conical production line, resulting in less equipment setup, less scrap generation, and increased product resistance. Furthermore, Pulpa delivers CardBoard to its customer with the highest longitudinal traction on the market, guaranteeing its traceability from the selection of raw materials to the final product.

CAPACITY

2.000

Installed Production

1.600mm

Machine width

70mm

Minimum formats

1.600mm

Maximum Formats

APPLICATION

Our paper is a versatile and resistant material, which can be applied in different sectors of the industry, such as for the production of tubes (which are used in the manufacture of toilet paper), in the food, textile industry, among others. In addition, our paper it can also be used for the production of barrels, which are cylindrical containers used for storing and transporting paints, textures, etc.. In civil construction, our paper can be used to make tubes for the production of structural, finishing and decorative columns.

120 a 260 g/m²

Used in the manufacture of paper tubes in the tissue sector:

Paper Tubes:

- Toilet Paper

- Towel Paper

- Aluminum Paper

261 a 420 g/m²

Used in the manufacture of tubes and barrels:

- Tubes

- Barrels

Technical Team

Polpa Papéis has a technical team with extensive knowledge to indicate the best grammage for your business, get in touch and answer your questions.

Eduardo Macedo

eduardo@polpapapeis.com.br

Tiate

gercomercial@polpapapeis.com.br

PROCESS

QUALITY AND SAFETY

Polpa Papéis has a laboratory equipped with state-of-the-art measuring instruments and trained professionals to maintain quality and follow the specifications required by each client.

We develop exclusive paper for each client.

Technology and automation in the manufacture of maculature paper

Our production processes are automated and supervised by a technical team specialized in the manufacture of stained paper, considering that this is a key factor in ensuring greater productivity, autonomy and efficiency in industrial processes. We also have cutting-edge technology in the production of renewable energy, fully autonomous, with supervision for control and monitoring.

Export

Our products cross borders, we are present in Mercosul and our CardBoard is approved in the most demanding quality markets. We serve the entire segment of tissue tubes, heavy tubes, barrels and conical tubes from abroad;

Punctuality

We value the trust our customers place in choosing Polpa Papéis as a supplier. Therefore, we constantly invest in advanced technology, aiming to exceed your expectations and ensure safe and agile product delivery.

From ordering the product to final delivery, each stage of the packaging and shipping process is carried out with precision and dedication.